In this text ultrasonic welding machine Detailed information will be discussed.

What is an Ultrasonic Welding Machine?

Ultrasonic welding machine is used for joining non-metal plastic parts such as iron and steel. This machine, which has a fast assembly feature, is frequently preferred in the industrial sector. It is known as a low-cost and environmentally friendly product. No silicone, adhesive or stabilizer product is required during joining operations with this welding machine. Therefore, it not only saves money but also contributes to the production of more durable products. It is among the environmentally friendly products as it does not require chemical products.

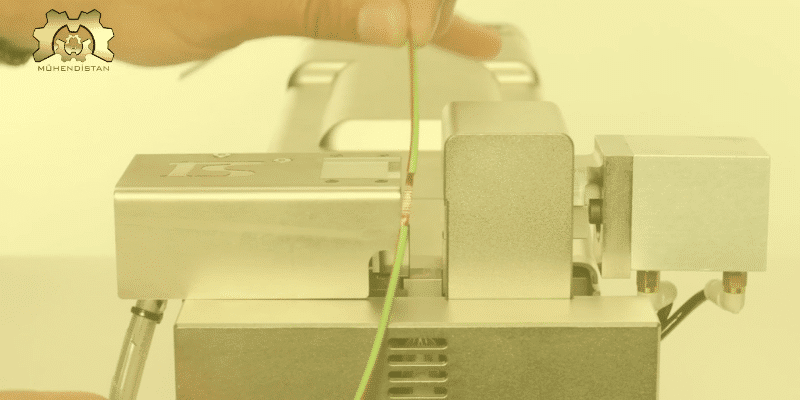

ultrasonic welding machine Different operations can be performed with . Solid plastics, films and artificial products can be joined with this machine. These machines have a part called horn. This part is required for continued operation. It has the feature of working manually or automatically. This machine, which has a time memory option, also has panels showing voltage and current.

The ultrasonic welding machine consists of an ultrasonic power supply and mechanical pressure system. The ultrasonic power supply converts the electrical energy it receives from the network into an electrical signal with a frequency and amplitude that the ultrasonic crystal can turn into vibration. This resulting electrical signal is fed with the ultrasonic crystal. The ultrasonic crystal converts this signal into mechanical vibrations. The booster amplifies the low amplitude vibrations created by the crystal to a point where they reach the melting point of the material to be welded.

Ultrasonic welding machine for plastics is considered a part of melt welding processes. The process is based on the conversion of friction and vibration energy into heat. By using a welding tool called Sonotrode (Horn), high frequency vibrations produced by the ultrasonic system are transferred to the parts to be joined together with pressure. This causes relative vibrations in the joining region.

Micromelt resulting from frictional heat during welding provides a vibration barrier that causes vibration energy to be absorbed and converted into heat. This then causes the weld contour to melt in fractions of a second, thus forming a molecular bond. The plastic parts to be welded must have a weld contour corresponding to the material type and weld seam requirements.

The contours focus energy input and result in very short sealing time. During ultrasonic sealing, heat is generated inside the foil. This means that no external heat input is required. The tools used in the welding process remain cold. The energy of the heat entering the product is very small. The temperature change between the carrier and the sealing layer occurs very quickly. This results in very good hot stitching.

What are the Features of Ultrasonic Welding Machine?

Ultrasonic welding machine has many features. These are as follows:

- Surface preparation before welding is quite easy.

- Pieces with different melting degrees are combined.

- Since materials such as additional metal, gas, or electrode are not used in the ultrasonic welding method, the problems that these may cause are not observed.

- No additional processing is required after welding. A clean job emerges.

- Due to the low value of friction heat occurring during welding, the HAZ zone does not occur.

- Process temperatures are below the melting temperature.

- After welding, no dimensional distortion occurs due to the effect of heat, and no creep is observed.

- Since there is no loss of time, processes such as cooling, surface cleaning, etc. are completed quickly.

- It is a welding method very suitable for automation. Process standardization and control are easy.

- With this welding machine, very thin cross-section materials and wires can be joined without any problems.

- It enables the welding of materials that are difficult to mold and combine, such as ceramics, glass and thermoplastic.

- It is very safe in terms of worker health and safety. There are no effects such as beam, smoke or gas in the ultrasonic welding machine.

- The way this welder is operated is simple. It is also comfortable to use.

- It is safer both in terms of production efficiency and because it does not harm human health.

How Does Ultrasonic Welding Machine Work?

The ultrasonic welding machine receives 50 Hz from the mains power. It increases the frequency of electrical energy to 20,000 Hz in the power generator. The converter converts electrical energy into mechanical vibrations thanks to piezoelectric crystals. The frequency of vibration is still 20,000 Hz. Thanks to the part called Booster, the amplitude of the vibration is increased or decreased according to the ultrasonic application to be made. One of the most important parameters in the ultrasonic welding process is the amplitude of vibration. Because the melting temperature and body structure of each thermoplastic material is different. Using an amplitude appropriate to the process to be done changes the result of the work to be done. The vibration reached to the desired amplitude is transferred to the plastic parts to be welded, thanks to the welding mold (Horn). The vibration stops when the rubbing surfaces of the parts, which rub against each other 20,000 times per second under pressure, reach the melting temperature. The parts are allowed to cool by waiting for a while under pressure. This total time is less than 1 second in most applications.

What are the Usage Areas of Ultrasonic Welding Machine?

Ultrasonic welding machine is used in many areas. These fields are as follows:

- automotive industry

- Packaging manufacturing industry

- chemical industry

- medical industry

- Electrical and electronic industry

- Filter and purification devices

- Toy production sites

- stationery industry

- Plumbing products production sites

- Plastic manufacturing industry

Conclusion

Ultrasonic welding machine is very popular in various sectors due to its easy use and environmental friendliness. This pocket-friendly welding machine is the result of the development of ultrasonic technology. If you liked this article we wrote about this machine, which is becoming increasingly popular, and found it useful, you can share your opinions with us.