Companies today use a wide variety of packaging made from a wide variety of materials to display their products on the shelves. Plastic packagings is one of the most used packaging.

Companies customize their plastic packaging through a variety of printing ways to stay ahead of the competition on the shelves. IML printing has also been seen as one of the most practical and attractive ways to customize packaging for many years.

What is IML?

“IML”, which is derived by combining the first letters of the words “in mold labeling”; It is a labeling technique preferred by more and more businesses every day, in which the label to be used in printing is embedded in the plastic package inside the injection mold.

How to Apply IML?

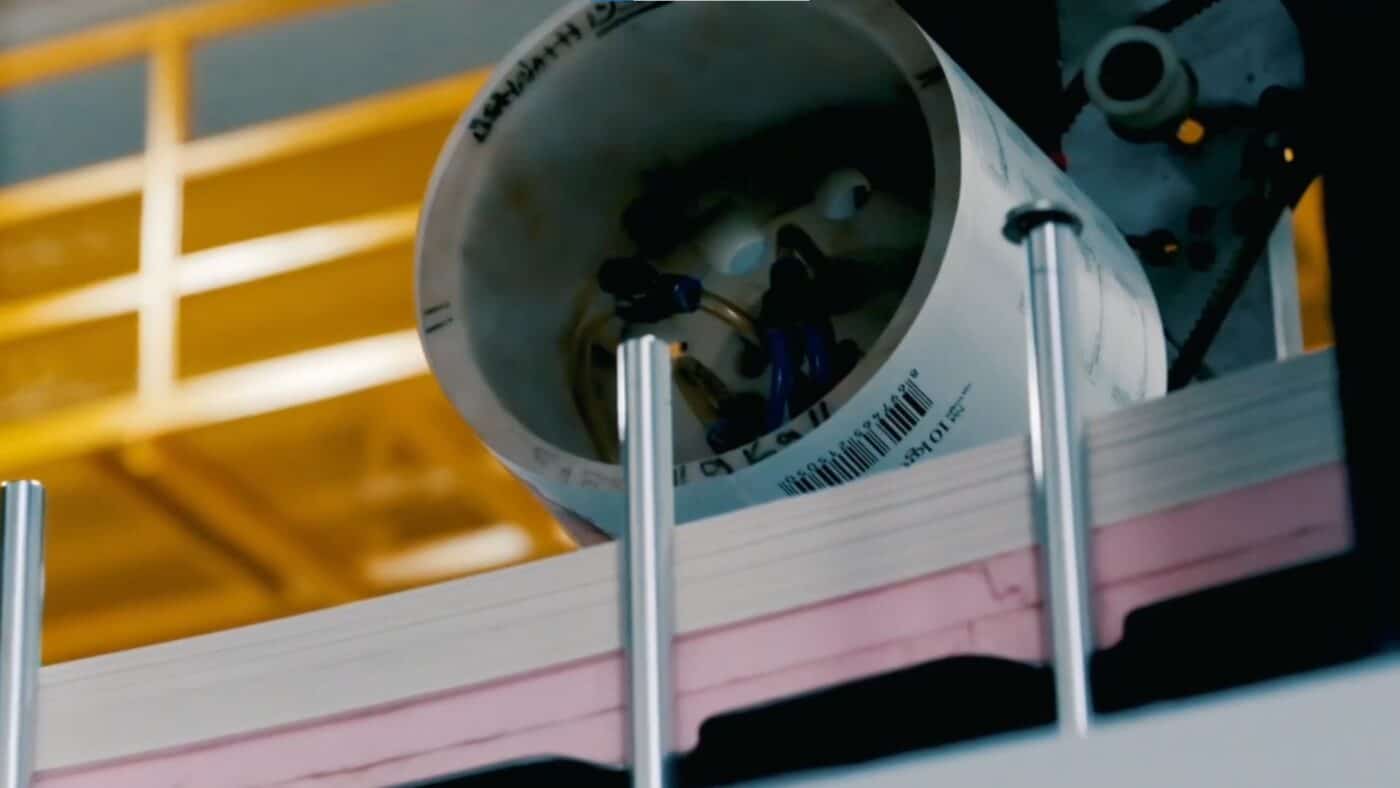

In-mold labeling (IML) is very different from other labeling techniques. In-mold labels (IML labels) are put into the mold with IML robot systems before the molds are closed. After the molds are closed, molten Polypropylene is injected into the mold. The IML label melts and adheres to the outer wall of the plastic product produced. As a result of this process, the final product produced with high printing quality is obtained.

What kind of a label is used in IML Printing?

The label used in IML (in-mold labeling) technology is usually made of PP (Polypropylene) raw material and colored by offset printing.

Since polypropylene is a raw material that can withstand high temperatures, it can remain intact in the hot injection mold. You can find more detailed information about polypropylene in our article titled “What is Polypropylene?”

What are the Advantages of Using IML Printing?

- The raw material of the in-mold labels (IML Labels) and the plastic products produced are the same. This makes it easy to recycle the product. It is an environmentally friendly method.

- IML labels increase the abrasion and heat resistance of the plastic product.

- IML labels improve the waterproof feature of the plastic product it contains.

- Since IML labeling is a labeling method that takes place simultaneously with plastic injection, it saves time and cost.

- IML labels produced from polypropylene have a glossy appearance and are eye-catching. It causes a positive effect on the sales of the products.

- IML labeling Thanks to IML robot systems, it provides hygienic labeling without human touch.

As a Result

Packaging products produced with the IML technique offer a wide variety of product design possibilities. Maximum visual advertising and information areas have sectoral diversity with very different volume options. If you are looking for IML printed special design packaging solutions for your business, you can contact us via the WhatsApp button at the bottom right or via the e-mail address [email protected].

Hi

Thanks for the clear explanation.

Please read about us on our website.

Kind Regards

Alice:https://zetarmold.com

Thank you very much for your analysis. Our company is engaged in injection molds . Our company’s website is https://zetarindustry.com. We are happy to serve you.Welcome to contact us.