What is (PP) Polypropylene?

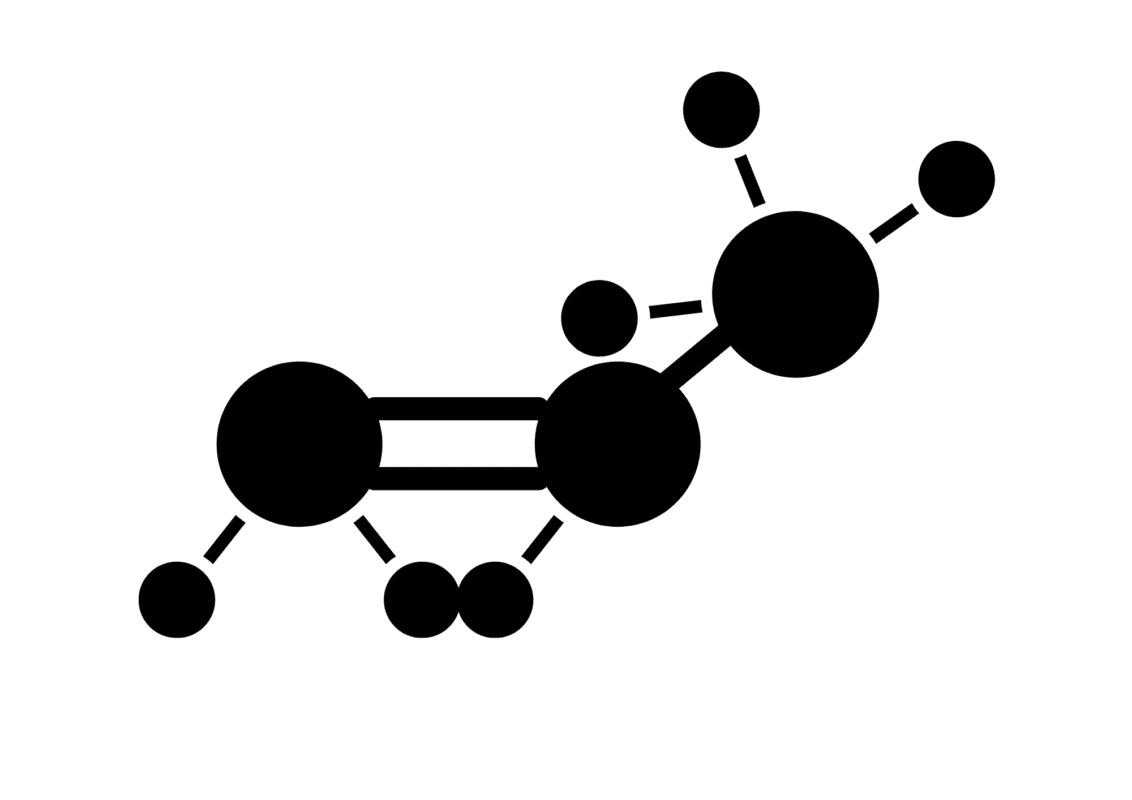

Polypropylene named by the abbreviation PP; due to its lightness, durability and resistance to chemicals, it is one of the most used raw materials in production and consumption in the world. It belongs to the group of polyolefins and is obtained in the process of polymerization of propene. The atomic structure of monomer propyls is CH2=CH-CH3.

What are the Properties of (PP) Polypropylene?

Physical Properties of (PP) Propylene:

• PP is a white colored substance with a translucent appearance. It is odorless and solid.

• The specific gravity of PP is low. It is 0.90-0.91 in terms of gr/m3. In this way, the products produced with PP are light.

• PP is relatively easy to process compared to other plastic raw materials. Generally, mold injection method is used in production.

• It has a thermoplastic structure. Its thermoplastic property makes it a preferred material for the manufacture of products of various shapes and sizes.

• Maintains its hardness even after severe physical stress. It can be further strengthened if needed.

• Air permeability is good while passing humidity at a low level. In this way, the products stored in PP are protected against moisture.

• It has good electrical resistance.

Chemical Properties of (PP) Polypropylene:

• PP is resistant to many chemicals with high acidity and basic properties.

• On the other hand, it is very sensitive to some solvents such as carbon tetrachloride.

• Odorless. It has no detected toxic effects. It complies with the food regulations.

• It is resistant to fungi and bacteria.

• It can be used at temperatures up to 121 °C without losing its properties, but when the temperature rises above 270 °C, its chemical structure decomposes.

• Propylene can be sterilized and used because of its thermal fusion (melting temperature) of 175 °C.

Advantages and Disadvantages of Using (PP) Polypropylene

| Advantages | Disadvantages |

| PP is a relatively inexpensive material. | It is transparent only in thin sections. |

| It is heat resistant. | It is a slow burning substance. |

| Sterilization is possible. | Measurement tolerance is low during injection. |

| It has low moisture permeability. It does not create moisture. | It is resistant to some solvents. |

| It is not toxic. | |

| Resistant to most chemicals. | |

| It is tough and durable. |

What are the Uses of (PP) Polypropylene?

Due to its non-toxic effect and low moisture permeability

• In food packaging

• In toy production,

• In the interior design products of cars,

• In the production of hard-covered suitcases,

• In the production of plastic cases,

• In medical fields such as laboratories, chemical product packaging, surgical suture threads and surgical mask production,

• In packaging stretches and films,

• Personal products such as combs, feeding bottles

• In household goods made of plastic material

• In kitchen products such as cutting board, grater, knives

• In installation pipes

The product produced from PP raw material is preferred.

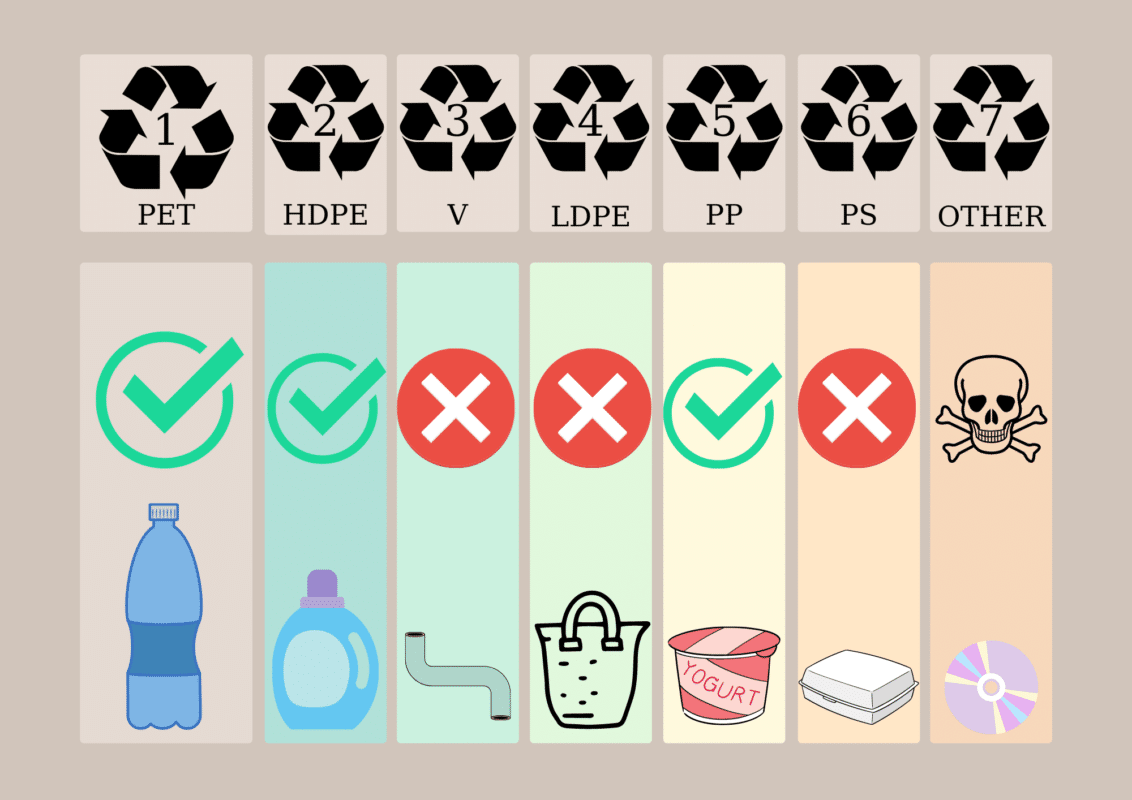

Is Polypropylene Recyclable?

The recycling code of polypropylene, which is a very safe plastic, is 5. In other words, there is no harm in recycling polypropylene (PP) raw material products many times, emptying and reusing polypropylene packages. There is no harm in refilling the liquids in these containers and reusing the container. In addition, PP is accepted by many recycling companies.

Is Polypropylene Safe?

Polypropylene is considered one of the most reliable types of plastic. PP packaging is especially used in food packaging, feeding bottles, yogurt containers, ketchup bottles.

It has been declared by health authorities that it does not pose a health problem when used in environments that do not exceed 270 °C, the temperature value at which PP begins to decompose. In other words, it is definitely not a toxic substance when the specified conditions are followed.

As a result

Polypropylene has become such a widely used chemical material that today it is difficult to imagine individual living spaces without products made from propylene. With its durability, reliability and quality appearance, propylene (PP) packaging will be the right solution for your business that needs packaging.

Click here to see the products of Divan Packaging, a polypropylene packaging factory.

Click to watch our promotional video.